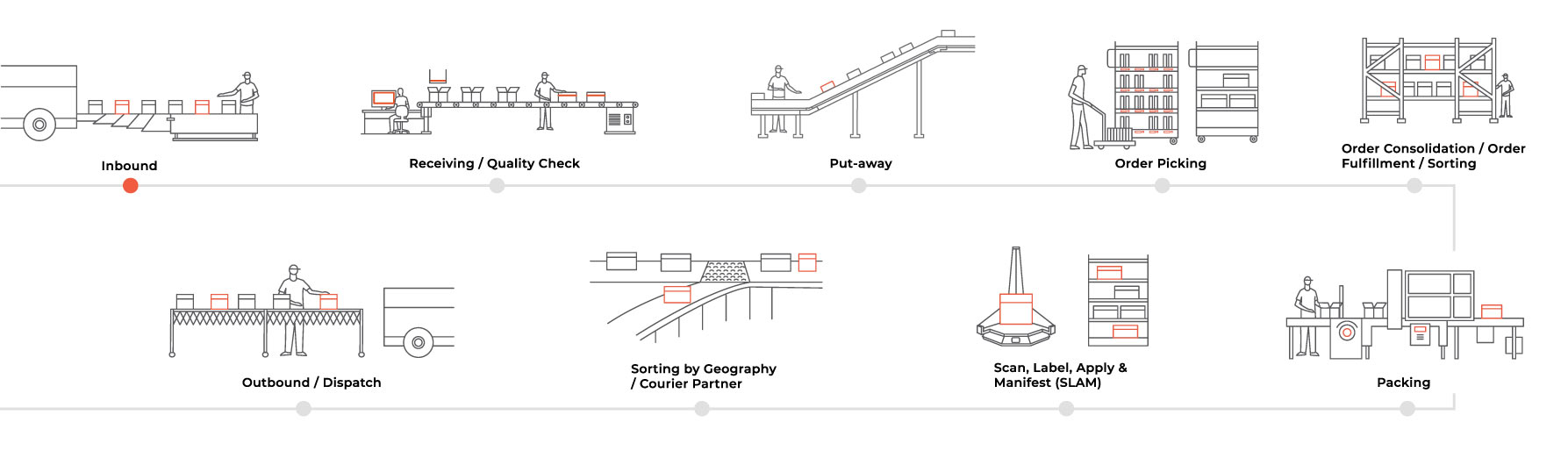

Receiving/ Quality Check

A range of automation solutions to maintain accurate inventory levels, ensure product quality,

and facilitate timely order fulfillment.

Receiving and quality check are critical control points in any warehouse operation, where errors or oversights can ripple downstream into inventory mismatches and customer dissatisfaction.

A structured receiving and QC solution ensures that every item entering the facility is verified for accuracy, condition and compliance before it reaches storage.

By digitizing the receiving process, warehouses gain better control, eliminate manual errors and maintain inventory integrity. A strong QC layer also protects your brand by preventing damaged or incorrect items from progressing further into the supply chain.

MECHANIZATION SOLUTIONS – RECEIVING & QUALITY CHECK

AUTOMATION SOLUTIONS – RECEIVING & QUALITY CHECK

The warehouse receiving process is a critical component of supply chain management that involves the intake of goods and materials into a warehouse or distribution center. A well-organized and efficient warehouse receiving process contributes to accurate inventory management, enhances order fulfillment capabilities, and ultimately improves customer satisfaction. Implementing a combination of the above automation solutions can significantly enhance the efficiency and accuracy of warehouse receiving processes, allowing businesses to handle larger volumes of goods with greater precision.

NIDO’s automation solutions for receiving process will help you maintain proper quality control and vendor compliance with a strict inspection, accurate verification and efficient data usage.