Why Warehouses Struggle

Warehouses don’t fail from lack of effort; they fail when problems slip through unnoticed:

- Labels fail -> Inventory disappears.

- Damage passes checks -> Returns and disputes pile up.

- Returns backlog -> Capital and space get stuck.

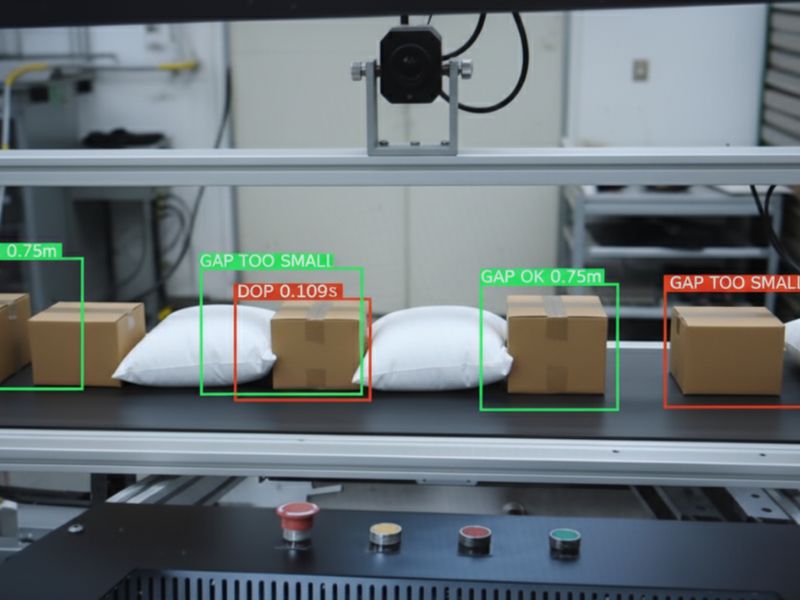

- Bins overflow, conveyors jam -> Throughput collapses.

- Pallets go missing -> Automation halts.

NidoEye stops these failures in real time across your warehouse.

One Suite. Ten Capabilities. Total Visibility.

NidoEye is an AI vision platform for warehouses and logistics, built to give you real-time visibility across parcels, pallets, and processes.

Instead of juggling fragmented tools, you get one integrated suite covering:

Below are four common scenarios NidoEye solves.

Why NidoEye is Different

NidoEye isn’t a generic AI tool. It’s engineered for the realities of high-volume Indian warehouses: