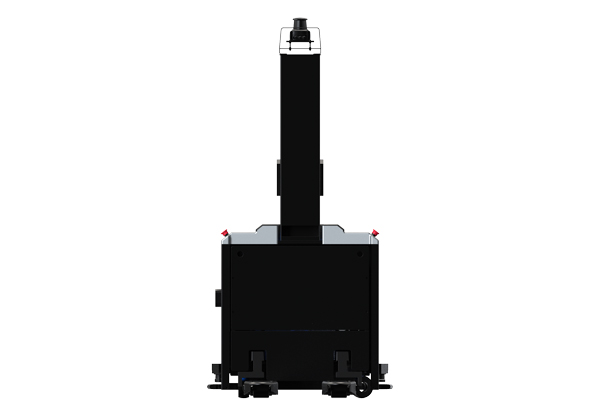

IZAR Pallet Handling AMR

With a compact structure and strong load capacity, our IZAR Autonomous Battery Operated Pallet Truck can significantly increase operating efficiency. Its built-in controller enables ±10mm high-precision positioning.

Features Of Our Autonomous Battery Operated Pallet Truck

Navigation Lasers

Carriers Recognition Kits

Fork Single Point Laser

360° Laser Protection

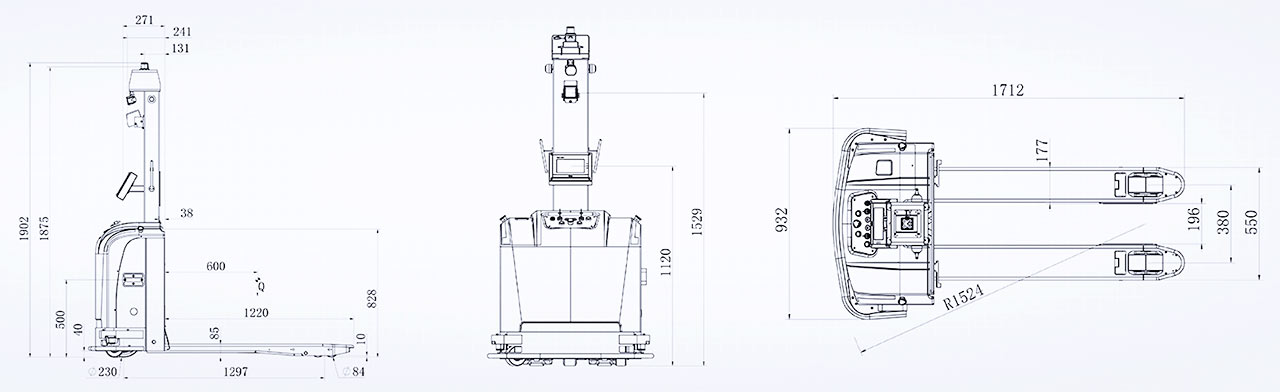

Technical Specifications

| IZAR 1500S Autonomous Battery Operated Pallet Truck | |

|---|---|

| Driving Mode | Automatic navigation, handheld driving |

| Navigation Type | Laser SLAM |

| Pallet Type | 3-Stringer Pallet |

| Rated Load Capacity | 1500 kg |

| Load Centre Distance | 600 mm |

| Wheelbase | 1297 mm |

| Dead Weight (with Battery) | 388 kg |

| Navigation Position Accuracy | ±10 mm |

| Navigation Angle Accuracy | ±1° |

| Standard Lifting Height | 120 mm |

| Fork Surface Ground Clearance (Lowest Position) | 85 mm |

| Navigation Laser Scanning Height | 1875 mm |

| Vehicle Size (L × W × H) | 1712 × 932 × 1902 mm |

| Fork Size (L × W × H) | 1220 × 170 × 70 mm |

| Fork Outer Width | 550 / 600 / 680 mm |

| Right-Angle Stacking Channel Width (1000×1200, across forks) | 2252 mm |

| Right-Angle Stacking Channel Width (800×1200, along forks) | 2158 mm |

| Right-Angle Stacking Channel Width (800×1200, 1000 along forks) | 2016 mm |

| Map Area (Single) | ≤400000 m² |

| Minimum Turning Radius | 1524 mm |

| Battery Parameters | |

|---|---|

| Battery Specifications | 48V / 23Ah (Lithium iron phosphate) |

| Battery Weight | 15 kg |

| Comprehensive Battery Life | 6–8 h |

| Charging Parameters | 48V / 1C |

| Charging Time (10%–80%) | 1 h |

| Charging Method | Manual / Automatic |

| Battery Cycle Number | >2000 times |

IZAR IN ACTION

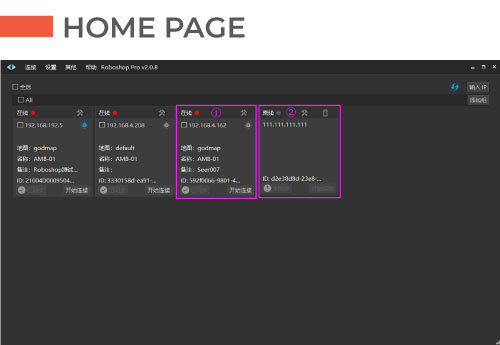

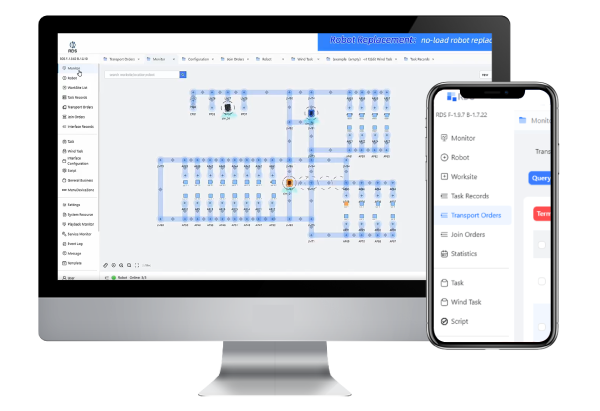

NAVIGATION & FLEET MANAGEMENT SOFTWARE

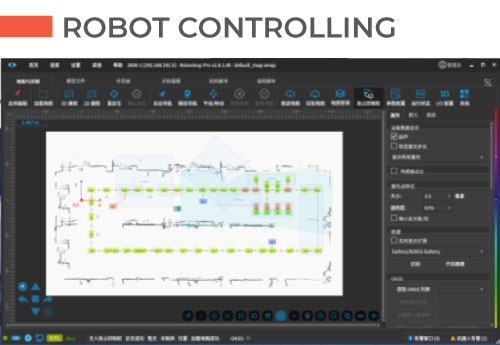

Roboshop is a one-stop implementation tool, which can uniformly manage and configure all intelligent device with built-in AMR core controller. Roboshop, a simple but strong software, provides an efficient solution for the implementation of smart logistics.

Manages and configures all intelligent equipment in the LAN uniformly, including robots, intelligent equipment and various automation devices based on the AMR series core controller.

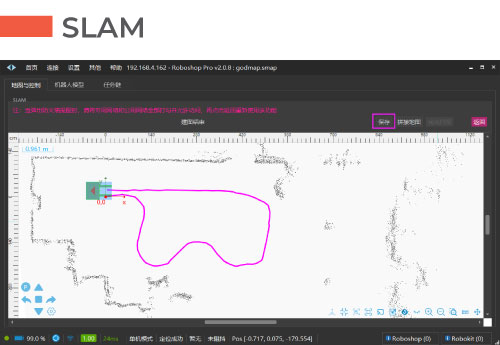

Simultaneous localization and mapping enables 2D or 3D maps to build accurately and efficiently.

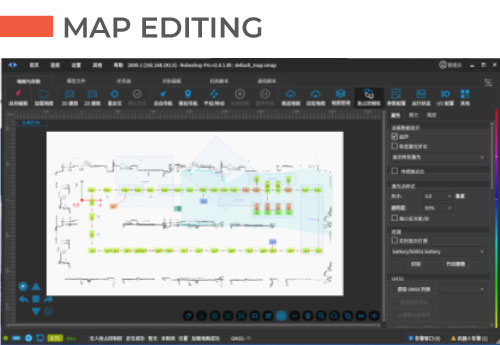

With easy-to-use map editing tools and high details control, it can be smoothly edit even for large maps and what you see is what you get.

The robot is controlled in real time. The manual and automatic modes are freely switched, and the API commands are fully covered.

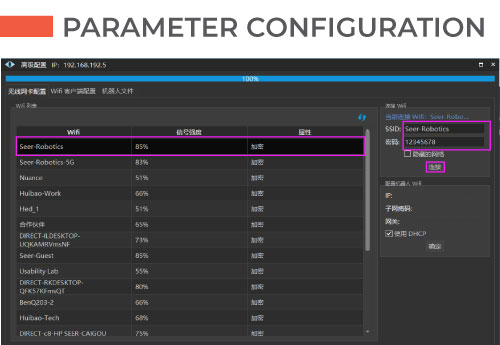

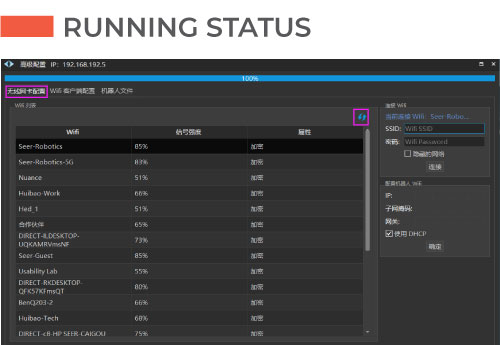

Rich configurable parameters to grasp details at your fingertips. Running status detailed status monitoring to get robot data at a glance.

Detailed status monitoring to get robot data at a glance.

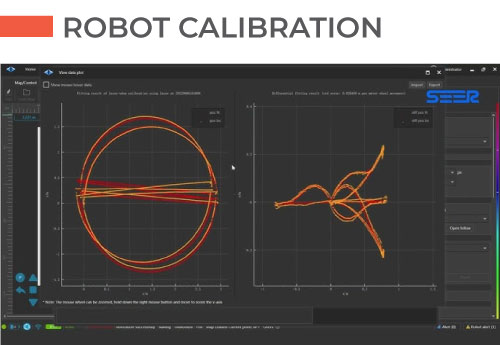

Automatic calibration process eliminates mechanical and assembly errors to ensure the consistency of multiple robots.

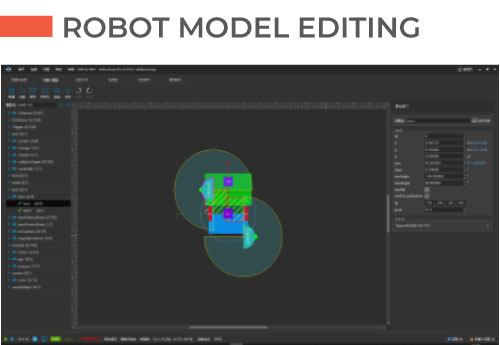

Visual robot model editing covers size, motion model, drive model, lidar model, motor position, sensor position, peripheral mechanism and more, thus robot making is as simple as building blocks.

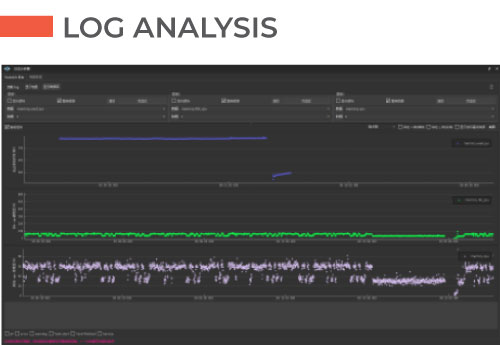

Integrated lof analysis tool analyzes robot running logs automatically easy to check errors.

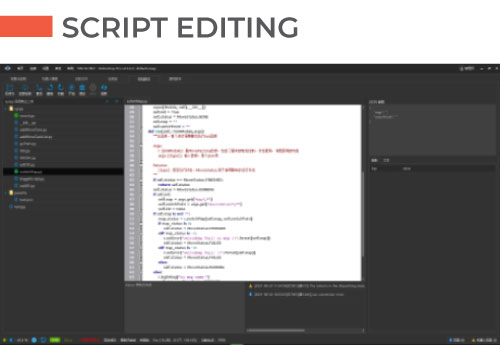

With python script programming, it’s beyond doubt to control however complex the peripheral mechanism and logic are.

Visual recognition object model editing allows all kinds of shelves, racks, pallets and cages to recognize online.

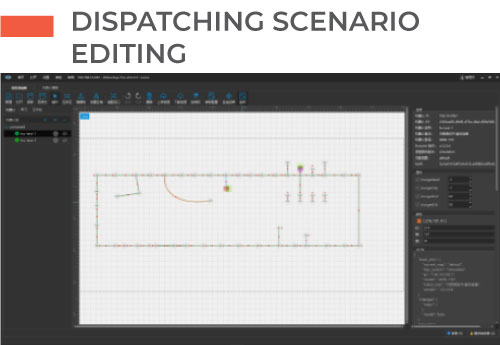

Integrated with RDS fleet management system, scenario editing adds such senses as multi-type and multi-floor robot maps, charging stations, mutually exclusive areas, lifts, traffic lights, control cabinets, and automation device for dispatching management.

FLEET MANAGEMENT SYSTEM

RDS Fleet Management System is a new generation dispatching system for mobile robots and factory automation logistics equipment. It provides customers with efficient solutions to quickly build application scenarios through a low-code business process engine, support business in transformation and upgrade to intelligent manufacturing.

Robot Dispatch

Worksite Management

Device Management

Eliminate complex device configuration, support automatic door, pager, charger, worksite photoelectricity, electric control cabinet, elevator and other devices, user-friendly and realize intelligent linkage with multiple devices.