During last year’s festive sales, a leading e-commerce warehouse suffered a major breakdown in their sorting system. Results?

- 40% of orders were delayed

- Customer complaints skyrocketed

- Returns piled up

- Losses crossed ₹1 crore

- Many festive promises got shattered

While large warehouses may have the resources to recover from such disruptions, growing warehouses, especially small to mid-sized operations can’t afford that kind of risk.

What they need is a solution that is modular, scalable, intelligent and built specifically to grow with them.

This is where ASTRO, the intelligent Grid Based Sorting and Fulfillment System by NIDO, comes in. Designed for fast-growing small to mid-sized operations, ASTRO helps warehouses scale smoothly, automate smartly and stay competitive

What Makes Small to Mid-Sized Warehouses Different?

Limited Space, High Expectations: Traditional automation systems demand large footprints and fixed layouts. In contrast, small to mid-sized operations must maximize every inch of space with compact and modular systems.

Budget-Conscious, ROI-Focused: High CAPEX is often difficult to justify. These operations need automation that can scale gradually, delivering measurable ROI at every stage.

Fast-Growing SKU Complexity: As businesses scale, their SKU count expands, adding to the sorting complexity. Manual processes can’t keep up and rigid systems can’t adapt.

High Sensitivity to Downtime: For small and mid-sized warehouses, even brief downtimes can have major consequences. Systems need to be reliable, serviceable and resilient.

How ASTRO Solves These Challenges?

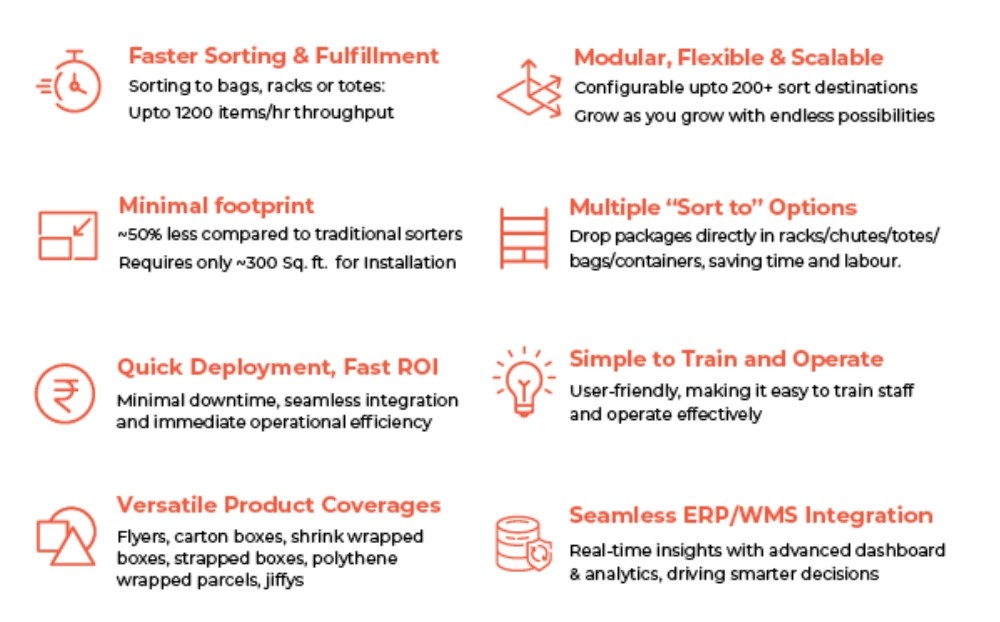

Compact Design for Constrained Spaces: Scales vertically or horizontally to increase volume or destinations – all within a footprint as small as 300 sq. ft.

Scalable System that Grows With You: ASTRO grows with your business — whether it’s increasing throughput or adding more destinations, it adapts seamlessly to your evolving needs.

Faster ROI: Quick deployment, minimal infrastructure changes and immediate productivity gains help you recover your investment sooner.

Adaptable to SKU Complexity: Efficiently sorts flyers, carton boxes, shrink-wrapped and strapped parcels, polythene-wrapped items, and jiffys with ease.

Features of ASTRO

Why ASTRO Is the Future of Sorting

4X Faster Than Manual Sorting: While manual sorting handles just 300–500 items/hour, ASTRO processes up to 1,200 items/hour, significantly boosting throughput with minimal manpower.

70% Space Savings for Compact Facilities: Unlike legacy sorting systems, ASTRO optimizes vertical real estate, making it ideal for urban fulfillment centers or small-sized DCs.

Flexibility for Irregular or Fragile Items: Where traditional sorters struggle, ASTRO excels. It adapts chute sizes and workflows for soft goods, returns or mixed SKUs.

ROI in 1.5 Years: While typical systems take 3-5 years for payback, ASTRO delivers ROI in 12-18 months through labor reduction, space savings and throughput gains.

Watch ASTRO in Action

As order volumes surge, SKUs diversify and customers demand faster delivery, small and mid-sized warehouses can no longer rely on manual processes or oversized fixed automation.

ASTRO is the smart, scalable path forward.

It grows with you, adapts with you, and most importantly – performs with you.