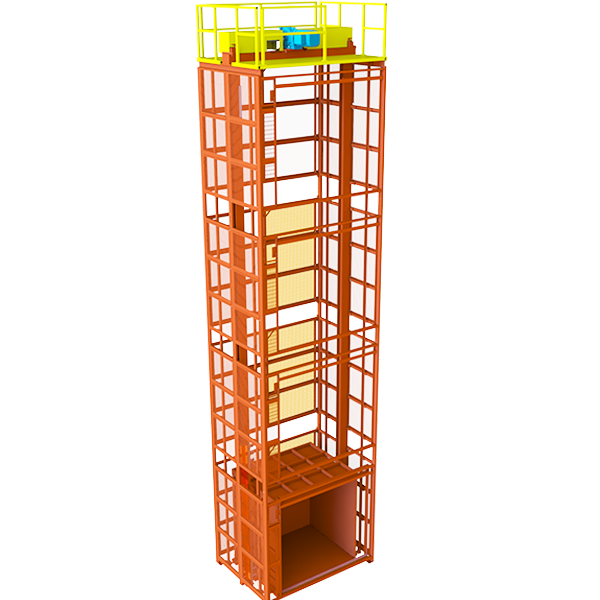

CANOPUSVERT Vertical Reciprocating Conveyors (VRCs) are designed to safely move materials between different floor levels in factories, warehouses, and multi-tier mezzanines. These electro-mechanical lifts operate in a reciprocating motion and are typically integrated with horizontal conveyors for seamless material transfer.

Our VRCs use electro-mechanical lifting mechanism to move goods vertically in a reciprocating motion. They can be integrated with conveyors for automated material flow or used as a standalone vertical lift.

Ideal for a Range of Industrial Applications

-

Warehouses & Fulfillment Centers: Move packed cartons, totes, and parcels between ground floor and mezzanine levels without manual lifting or forklifts.

-

E-commerce Operations: Efficiently transfer sorted orders from picking zones to dispatch areas across multiple floors.

-

Manufacturing Units: Lift semi-finished or finished goods between production stages on different levels.

-

Automated Storage Systems: Connect vertical storage units or AS/RS systems with other levels for seamless order flow.

-

Retail Back-End Logistics: Transfer inventory from receiving zones to overhead storage or retail replenishment zones.

| Feature | VRC Elevator | Conventional Goods Lift (VCR) | Winner |

|---|---|---|---|

| Installation Cost | Much Lower | Higher | VRC |

| Cab Size / Capacity | Larger | Smaller & Costly | VRC |

| Pit Requirement | Not Required | Required | VRC |

| Construction Quality | Robust (Industrial Grade) | Lighter | VRC |

| Maintenance Requirement | Very Less | High | VRC |

| Machine Room | Not Required | Required | VRC |

| Total Cost of Ownership | Much Lower | Higher | VRC |