Industry Challenges in Sorting Operations

How We’re Addressing the Challenges

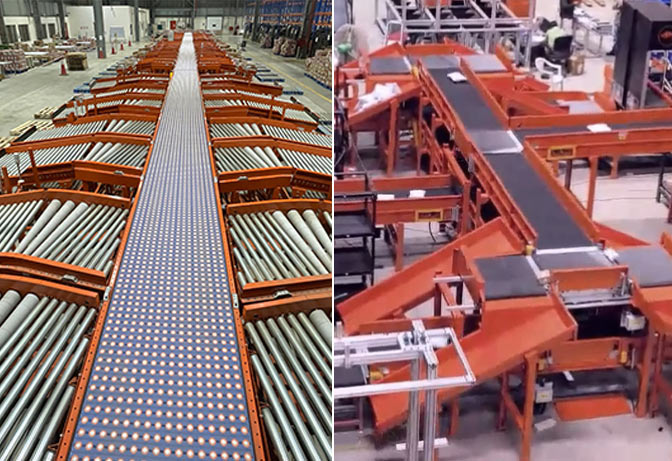

NIDO designs, develops, and manufactures a comprehensive range of sortation systems for a wide variety of products—capable of delivering high throughput with exceptional precision. With a dedicated in-house team of control engineers and software experts, we provide tailor-made solutions that align perfectly with your operational needs.

Our sortation solutions automate the entire process within your distribution center, from goods receipt to sorting and dispatch – eliminating inefficiencies, minimizing material wastage, and optimizing resource utilization.

As a one-stop partner for sorting automation, our systems are engineered to turbocharge your operations from start to finish, ensuring unmatched accuracy, speed, and scalability.