Client Overview

The client operates a fast-paced warehouse where speed, space efficiency, and safe product flow are critical. With increasing order volumes and limited vertical space, the client needed a compact and reliable solution for moving totes between floors.

Challenge

- Limited floor space in a multi-level warehouse

- Need for smooth, damage-free movement of totes

- Manual transfer between levels was inefficient and time-consuming

- Increasing fulfillment pressure due to growing daily order volumes

Solution

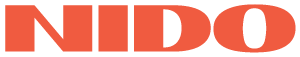

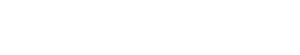

We supplied a Gravity Spiral Conveyor designed specifically to handle plastic totes with precision and safety. Key features included:

- Spiral configuration for vertical movement with minimal footprint

- Controlled descent using gravity, requiring no power

- Smooth rollers designed to protect totes from damage

- Durable structure to support 24/7 operations

Implementation Results

- Freed up valuable floor space

- Eliminated need for manual tote transfer between floors

- Improved overall order flow and dispatch time

- Reduced energy consumption with gravity-based design