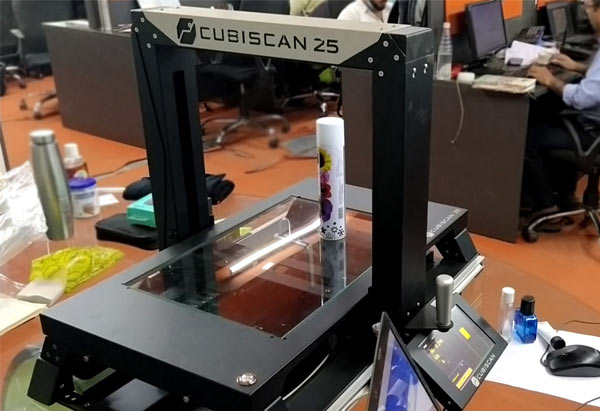

CUBISCAN DIMENSIONING & WEIGHING SYSTEM

Sensor Based Static DWS System for capturing the Dimensions, Weight, Barcode and Product Images for a variety of applications.

SENSOR BASED STATIC DWS SYSTEM

OUR DWS SYSTEM CAN HELP YOU IN

With our state of the art, automated dimensioning & weighing system, it is now possible for the carrier to accurately dimension & weigh freight without compromising throughput or the operation’s strict delivery schedules. Space equals to money and by optimizing it efficiently you can add more revenues while eliminating the manual, inaccurate and labour intensive processes. From warehousing and space management to shipping and receiving to logistics and transportation, we have a wide range of DWS systems to automate your dimensioning, weighing & scanning operations.

PARCEL SHIPPING

Incorporating dimensioning and weighing system into your warehouse shipping stations will save you money on parcel shipping costs, improve your manifesting efforts, and assist you in revenue recovery.

SPACE OPTIMIZATION

The package data provided by a dimensioning and weighing system can optimize your operation, leading to improved order fulfillment, carton selection, slotting projects, and overall warehouse efficiency.

WAREHOUSING & DISTRIBUTION

The data obtained from the system can be utilized for storage location selection, carton selection & shipment planning. By interfacing directly with the manifesting or WMS applications, it helps in data storage, transfer and validation when required.